3D Printing revolutionizes production by creating objects layer-by-layer from digital files. Discover technologies, materials, and industrial uses. According to the ISO/ASTM 52900 standard, this process is technically defined as “additive manufacturing,” clearly distinguishing itself from traditional subtractive techniques like milling, which remove material from a solid block.

Key Takeaways

- Definition: Creation of solid objects through the sequential addition of material.

- Digital Input: Requires a CAD (Computer-Aided Design) file converted into STL format or equivalent.

- Versatility: Uses polymers, metals, ceramics, and composites for sectors ranging from aerospace to medical.

What exactly is 3D Printing

3D printing represents a paradigm shift in the manufacturing value chain. Unlike injection molding, which requires expensive fixed molds, this technology is “tool-less”: the object is generated directly from mathematical data. This allows for nearly absolute geometric freedom, making it possible to create complex internal structures (such as lattices or conformal cooling channels) that are impossible to produce with conventional methods.

How the layer-by-layer process works

The mechanism underlying almost all printers is the division of the digital model into extremely thin horizontal sections, called “slices.” The slicing software instructs the machine on how to deposit or solidify the material for each single layer.

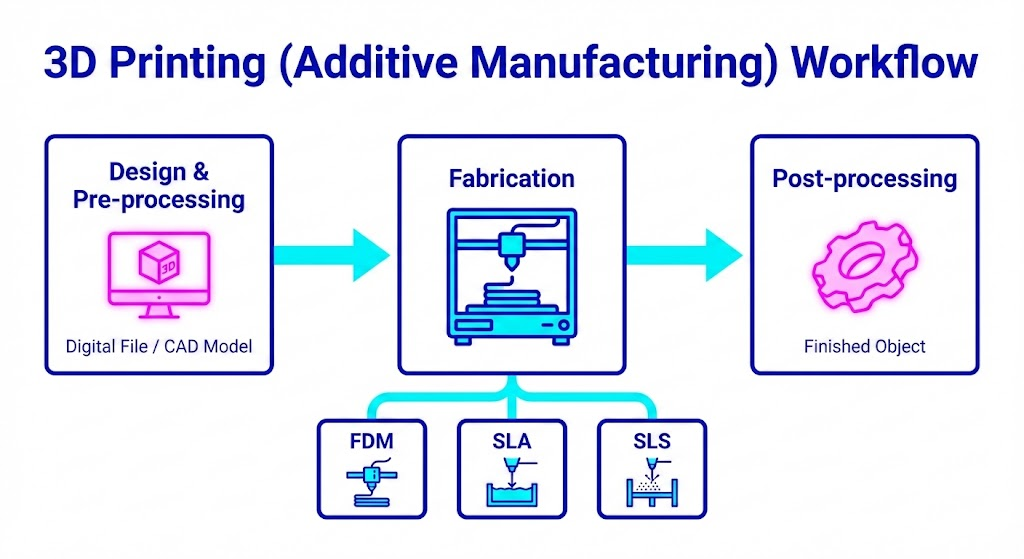

The production cycle follows three critical phases:

- Design and Pre-processing: Creation of the 3D model and orientation of the part on the build platform.

- Fabrication: The machine executes the deposition or fusion of the material (powder, filament, or resin) layer after layer.

- Post-processing: Removal of supports, surface cleaning, and any thermal treatments to stabilize mechanical properties.

The main 3D Printing technologies

Although the term 3D printing is used as a general umbrella, there are several technology families classified based on the state of the raw material:

- Material Extrusion (FDM/FFF): A polymer filament is melted and extruded through a nozzle. It is the most widespread technology for rapid prototyping.

- Vat Polymerization (SLA/DLP): A liquid photosensitive resin is selectively cured by a light source (laser or projector). It guarantees very high surface resolution.

- Powder Bed Fusion (SLS/DMLS): A high-power laser fuses powder particles (plastic or metal) in a controlled environment. It is the standard for high-performance functional parts.

Industrial applications and benefits

The adoption of additive manufacturing is no longer limited to rapid prototyping. Today it is an integral part of final production (Direct Digital Manufacturing) in strategic sectors. In aerospace, it allows for component weight reduction (lightweighting) while maintaining structural integrity, reducing fuel consumption. In the medical field, it enables the creation of custom prosthetics and implants perfectly adapted to the patient’s anatomy. The supply chain also benefits from the ability to produce spare parts “on-demand,” drastically reducing warehousing costs.